Aluminizing Business

Vacuum deposition processing

Vacuum deposition is a film-forming technology in which vaporized metal is applied (plated) to the surface of plastic products in a vacuum chamber. Products that have been subjected to vacuum deposition have a mirror-like surface, so they are widely used as reflectors for devices such as car lights, as well as for decoration of cosmetics, glasses, pachinko machine parts, etc.

Strengths

This is what makes BIKO 's vacuum deposition different!

Equipped with a class 10,000 clean room, we provide high-quality deposition services, including jig design.

■ We are equipped with one of the few Class 10,000 clean rooms in the industry!

We provide high-quality products made in an environment that is free of dust, fibers, etc.

*A number that indicates the cleanliness of a space. This refers to an environment in which there are less than 10,000 dust particles of 0.5 microns or larger in one cubic foot of air (approximately 28 L).

The Need for Clean Rooms

Traditionally, headlights and taillights installed in automobiles had a step in the lens, making it impossible to see inside. However, in recent years, lamps have become more well-designed, allowing you to see inside. Dirt and scratches are no longer tolerated, and there has been a strong demand for improved quality.

■ Deposition onto various materials is possible!

We have the technology to deposit onto various molding materials. We have experience depositing onto ABS, PP, PC, PC-HT, PET-PBT, PA, PAR, and PPS!

■ After molding, direct deposition onto the material reduces labor!

We own the latest plasma polymerization deposition equipment. This allows for polymerization deposition and direct deposition, eliminating the need for under- and top-coating processes, achieving high productivity, high quality, low cost, and environmental friendliness at the same time.

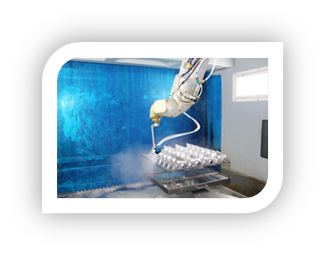

■ Stable painting by robots!

Robots perform all the painting from undercoat to topcoat and color coating, achieving high precision and high quality painting. Film thickness can be controlled in 1μm increments.

■ We can handle two types of paint drying!

We are equipped with both a thermal drying oven and a UV drying oven, so we can handle a variety of product specifications.

■ Design jigs in-house!

By creating our own jigs that take quality and ease of use into consideration, we can increase productivity and quality. We can also handle products with complex specifications and shapes.

■ We have a thorough quality assurance system

We carry out quality and performance evaluations in-house using various testing, measuring and analysis equipment, such as heat resistance testers, hot water testers, constant temperature and humidity testers, reflectance measuring instruments, film thickness measuring instruments, etc. This allows us to maintain and guarantee the quality and performance of our products.

The latest technology, laser decoration, has expanded the range of expression.

■ Improved design with laser decoration

Our head office has the new developing by using a laser decoration device, a variety of designs can be created by irradiating a laser onto the deposition film and peeling it off.

Vacuum deposition process (Aluminizing process)

1. Air blow

It is also possible to remove dust, lint, etc. that has adhered to materials (plastic molded products) by cleaning them with antistatic air.

2. Under painting

Robot painting allows high quality painting at high speed. Color painting, light blocking, metallic and top coat painting are possible.

3. UV drying

Dry in a heat or UV oven.

4. Vacuum deposition

Apply a coating to protect the plated surface (vacuum deposition surface). (If a deposition machine's polymerization device is used, the top coat is omitted.)

5. TOP painting

A thin metal film is formed on the surface of a material. It is vapor-deposited due to the characteristics of the metal. For example, a mirror finish is formed with aluminum. It is possible to coat the vapor-deposited plated surface by plasma polymerization after vapor deposition.

6. Surface inspection

Inspec the surface apperance of parts after finished aluminizing process every pieces for quarantee quality.

Product examples

If you have any requests or questions about plastic processing, please use our free consultation service . We will make proposals based on your purpose and budget. We can also produce prototypes.

Contact by phone ![]()

Business hours: 8:00-17:00 (excluding Saturdays, Sundays, and company-designated holidays)